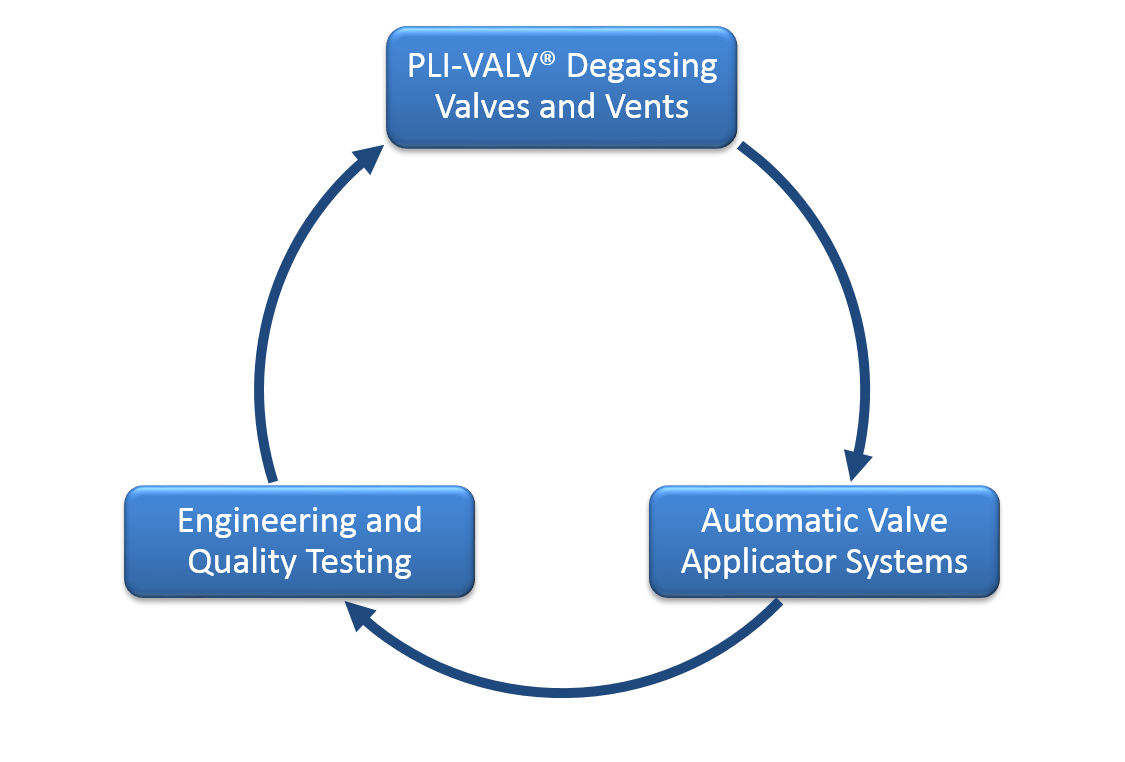

With over 50 years of expertise in providing customers with innovative die cut solutions, PLITEK® has remained the leader in precision die cutting and narrow web converting of films, foams, adhesive tapes, and other thin gauge materials. The die cutting manufacturing process entails utilizing specialized equipment and tools to convert stock material by slitting, cutting, laminating, forming, and sealing it into custom shapes and designs.

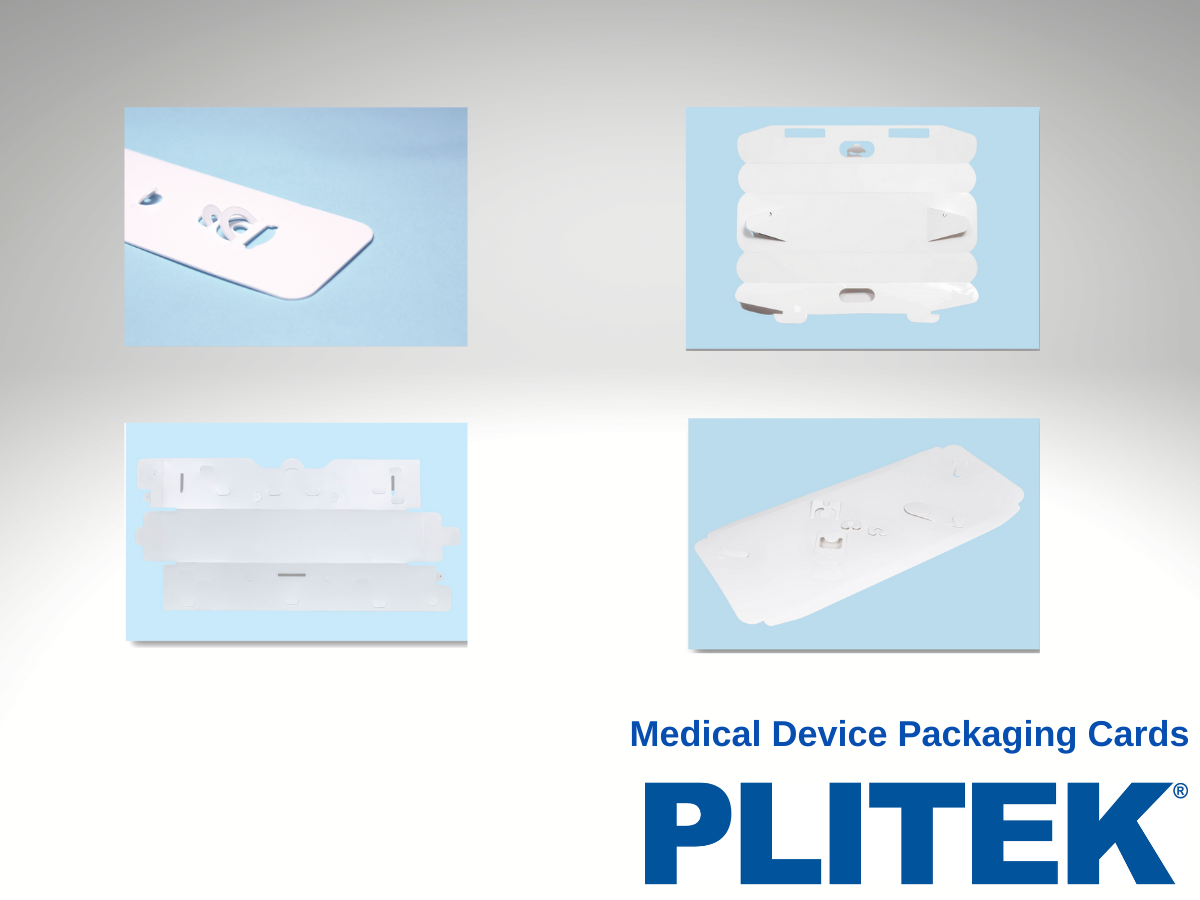

Innovative manufacturing capabilities, proven expertise, consistency, and strict quality standards keeps PLITEK® a continual leader in manufacturing of die cut parts and converted materials. PLITEK® is certified to ISO 9001:2015 and ISO 13485:2016 standards and is FDA, cGMP, and ITAR compliant. We are in the process of implementing and gaining compliance to Health Canada regulations.

Utilizing our state-of-the-art equipment, we work collaboratively and confidentially with our customers through all stages of their product life cycle from product development and prototyping to high volume production and fulfillment. Extensive die cutting capabilities enable us to produce precision components from a range of materials for a variety of applications. Die cut components can be supplied in piece, sheet, or roll form.

Capabilities:

-

ISO Class 8 clean rooms

- Precision die-cutting

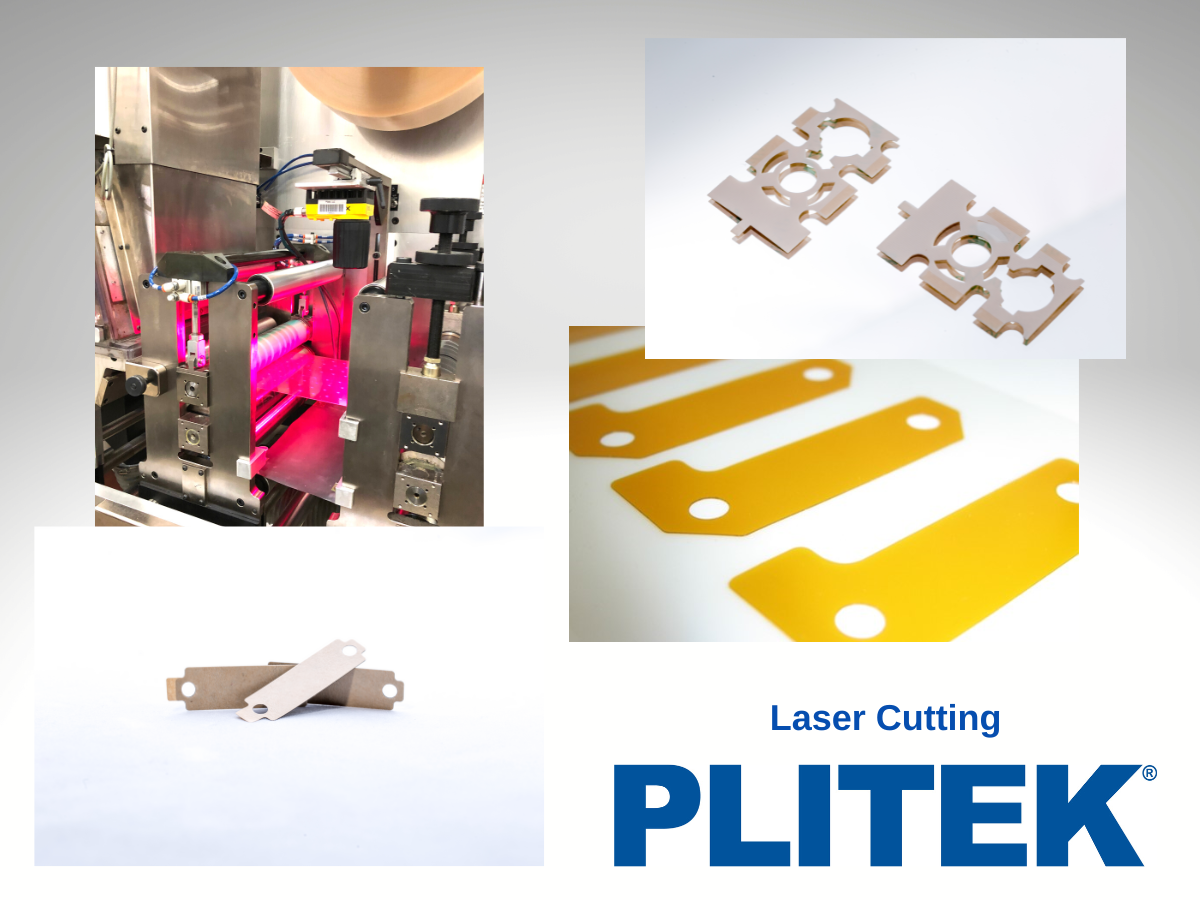

- Laser cutting

- Custom film extrusion

- Slitting

- Multi-layer laminating

- Adhesive coating

- Release liner coating

- Packaging and fulfillment

View product website