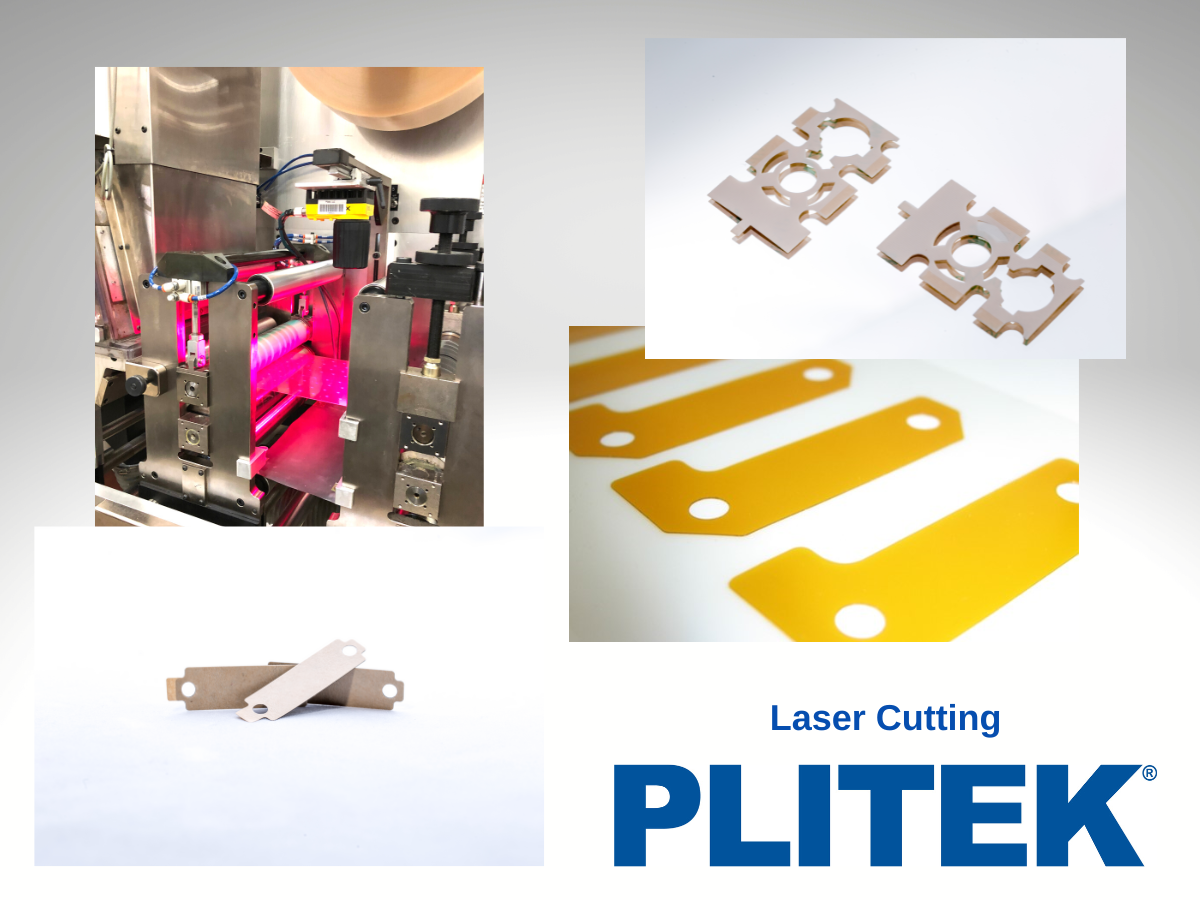

Laser cutting capabilities enable cutting of complex parts in registration and with tight tolerances. Laser cutting is a thermal process in which a focused laser beam is used to cut material in a localized area. A continuous cut is produced by movement of the laser beam through a galvanometer or xy head movement. The advantages of laser cutting include the ability to cut difficult materials without contact, verify cut pattern immediately, cut precision, repeatability, and quality. Tooling is not required, which helps with product lead time and cost, but can be added if needed. Utilizing our state-of-the-art equipment, we work collaboratively and confidentially with our customers through all stages of their product life cycle from product development and prototyping to high volume production and fulfillment. Laser cutting can be combined with other converting processes such as slitting, laminating, rotary die cutting, and pouching in one multi-station process.

LASER CUTTING CAPABILITIES

- 7 station rotary laser machine with integrated visual inspection system

- 300 watt CO2

- 400 watt CO2

- Flatbed digital laser system for small quantities and prototypes

- 50 watt CO2

- Kiss cutting

- Ablation

- Drilling

- Slitting

- Perforation

- Through cuts and slug removal

- Scoring

- Scribing & sequential numbering