Safely and Easily Secure Your High-Speed Rotational Needs!

Lake Zurich, IL, July 29, 2021 – Rotational capacity requirements for modern applications are higher than ever, especially in electric motors, gearboxes, and automotive transmissions. As the market leader for innovative retaining ring solutions, Smalley has been continually investing in ongoing research and development to meet the demand for high RPM requirements.

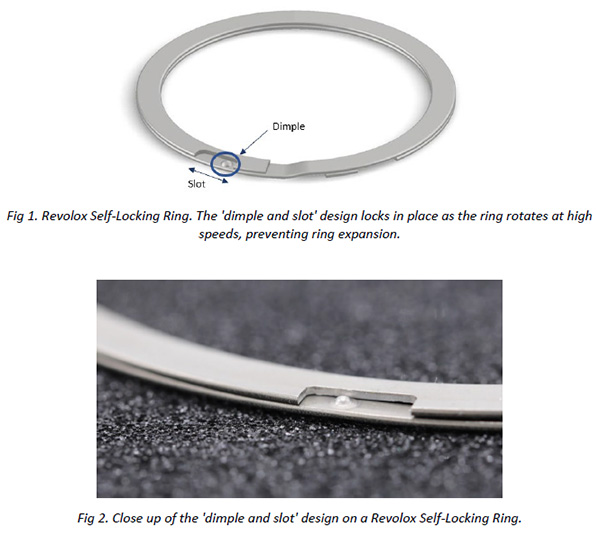

Smalley's latest retaining ring innovation, the revolutionary Revolox Self-Locking Ring, features a 'dimple and slot' design that safely and efficiently secures your application at high speeds.

The top five advantages of Revolox Self-Locking Ring include:

- Significantly higher RPM capacity over an equivalent non-locking retaining ring

Revolox Self-Locking Rings were tested and optimized for superior and secure high RPM performance. Contact Smalley Engineers to discuss RPM capabilities in your application. - Ease of installation

The sturdy 'dimple and slot' design is not easily damaged during installation. - Lightweight

With a part weight approximately half the weight of a typical retaining ring, the lower part weight reduces rotating mass and therefore increases efficiency in the application. - Automated installation capabilities

Automated installation capabilities make Revolox Self-Locking Rings an ideal solution for high production volumes. - Inherently better-balanced than snap rings

Revolox Self-Locking Rings have an inherently better-balanced design that helps decrease vibration.

"We are excited to introduce Revolox Self-Locking Rings to our growing selection of over 6,000 retaining rings," said Ken Massett, Vice President of Sales Engineering. "This new product will transform the way engineers design high rotational capacity applications by enabling them to design around high RPM requirements cost-effectively and with ease of assembly for high volume applications.”

Learn more about Revolox Self-Locking Rings and contact an Engineer for technical design support and guidance.

###

About Smalley: As the inventor of the edgewound wave spring and with over 100 years of manufacturing excellence, Smalley is the Engineer's Choice® in providing wave springs, retaining rings, and constant section rings for all of your application needs. Smalley stocks over 10,000 standard parts across 30 configurations and 400 sizes. Prototype or production volume, our team of industry-specialized engineers and No-Tooling-Charges™ manufacturing process meets the design flexibility your application, budget, and timeline requires. While all of our manufacturing is made in our U.S. based 300,000 ft2 facility, our global network of offices, engineers, and distribution partners allows you to receive parts and support quickly from anywhere in the world. As an ISO 9001 and ISO 14001 company, we deliver quality products certified to IATF 16949, AS9100, and ISO 13485. For manufacturing news and product updates, follow us on social media or follow our blog at smalley.com/blog

Media Contact

Brendan Briscoe, Marketing Operations Supervisor | +1-847-719-5900 ext. 5723 | [email protected]

View website