PTI Engineered Plastics, Inc.

PTI Engineered Plastics

From Mind to Manufacturing®

PTI Engineered Plastics specializes in custom injection molding and manufacturing of plastic components and assemblies. Our in-house tooling capabilities can produce injection molds in the turnaround time of a prototype, while meeting the expectations of production quality molds. From low to high volume, simple to complex, prototype to production, PTI is a single source solution. We focus on aggressive lead times and adhere to international standard compliances. PTI utilizes the most innovative technology and software, and perform all services, from design through manufacturing, within our 155,000 square foot facility. This enables us to maintain a competitive edge in cost, quality and delivery.

PTI Engineered Plastics specializes in custom injection molding and manufacturing of plastic components and assemblies. Our in-house tooling capabilities can produce injection molds in the turnaround time of a prototype, while meeting the expectations of production quality molds. From low to high volume, simple to complex, prototype to production, PTI is a single source solution. We focus on aggressive lead times and adhere to international standard compliances. PTI utilizes the most innovative technology and software, and perform all services, from design through manufacturing, within our 155,000 square foot facility. This enables us to maintain a competitive edge in cost, quality and delivery.Our advanced precision inspection and testing abilities address a spectrum of dimensional and functional product specifications and requirements. These capabilities support comprehensive inspection actions ranging from receiving to final audit, as well as first article layouts, full AIAG PPAP and IQ, OQ, PQ Process Validation Submissions. For more information on our capabilities, please visit: www.teampti.com

Design and Engineering for Plastics

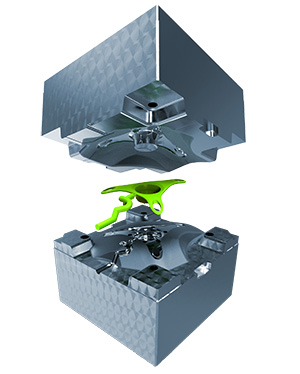

It starts with design; whether it’s new design or design assistance. Available to our customers’ is the full resources of PTI Design. On site designers and engineers will ensure your concept is designed for manufacturability. From product development, material recommendations, as well as moldflow services, our team will help you get your concept from mind to manufacturing.Tooling

Highly skilled journeymen mold makers build both prototype and production tooling for extremely complex geometries requiring tight tolerances. We utilize various materials to construct tooling including aluminum, all grades of steel and hybrids of both. We have 18 high speed CNC machining centers, 4 high-speed graphite machining centers and 3 Makino CNC EDM machines. The machining centers tie into a fully integrated tooling network, and can achieve spindle speeds up to 54,000 RPM utilizing heat shrink collet tooling. PTI is known in the medical industry for our highly detailed tools, multi-surface large parts, and scientific molding capability. Our P3 proprietary process provides the quick turnaround and the competitive edge necessary in this market by producing a superior tool that will meet the requirements for prototype through production.Injection Molding

PTI is FDA registered and ISO 13485 certified and for over 30 years has provided the medical industry with plastic injection molding components. Our press sizes range from 12 to 750 tons. This enables us to offer low and high volume production and the ability to produce custom rapid injection molded products. At PTI, we support engineered grade thermoplastic resins and have an array of finishes and colors.

PTI is FDA registered and ISO 13485 certified and for over 30 years has provided the medical industry with plastic injection molding components. Our press sizes range from 12 to 750 tons. This enables us to offer low and high volume production and the ability to produce custom rapid injection molded products. At PTI, we support engineered grade thermoplastic resins and have an array of finishes and colors.PTI also specializes in insert molding of plastic components. Looking for higher temperature molding? PTI has a high heat cell equipped with machines designed exclusively to run temperatures up to 460° F.

Cleanroom

Adhering to the strict protocol and methods, PTI meets the demands of industries requiring ISO Class 8 Cleanroom specifications, including bioburden and electrostatic discharge (ESD). PTI is home to over 4,000 sq. ft. of Cleanroom manufacturing.Services provided in the ISO Class 8 Cleanroom include:

- Injection molding

- Post-mold annealing

- Assembly

- Secondary operations

- Packaging

Validation

In this age of high-tech manufacturing, quality requirements have never been tougher. That’s why PTI Engineered Plastics has built their operations to support validations throughout their manufacturing and assembly processes. Our team is highly trained to define and implement all facets of IQ, OQ, PQ protocol validations, including many other quality standards required in the plastic injection molding industry.Value Added Services

Sourcing all your needs through one provider is what PTI is all about. That is why PTI offers a host of value-added services that include:- Product Assembly

- Supply Chain Management

- Packaging

- Plastic Joining

- Sonic Welding

- Spin Welding

- Heat Staking

- Part Decorating

- Pad Printing

- Laser Marking

- Hydro graphics

- EMI Shielding

- Painting and Plating

Awards

2017 Green Supplier of the Year - Yazaki North AmericaTop 100 Workplace 2017 Detroit Free Press

Champion of Workforce Development 2015 Macomb County