A new brushless motor option developed by KNF enables next level pump technology with unprecedented advantages

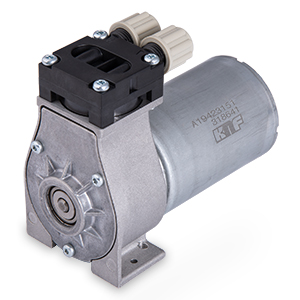

A pump is only as good as its drive. This insight led KNF to make a big step forward and to radically reinvent the entire drive unit including the motor, pump housing and mechanical drive components. The new KNF DC-BI relies on an advanced in-house developed brushless DC motor.

The Most Advanced Motor Option

As the innovation leader in diaphragm pump technology, KNF is known for customizing pumps to specific customer needs. The new motor option from the Digital Customization series further diversifies optimization options and pushes diaphragm pump technology to the next level. In addition to typical advantages of modern BLDC motors like long lifetime and controllability, KNF can now provide even more benefits for customers.

Fully Integrated Drive Unit Improves Multiple Pump Properties

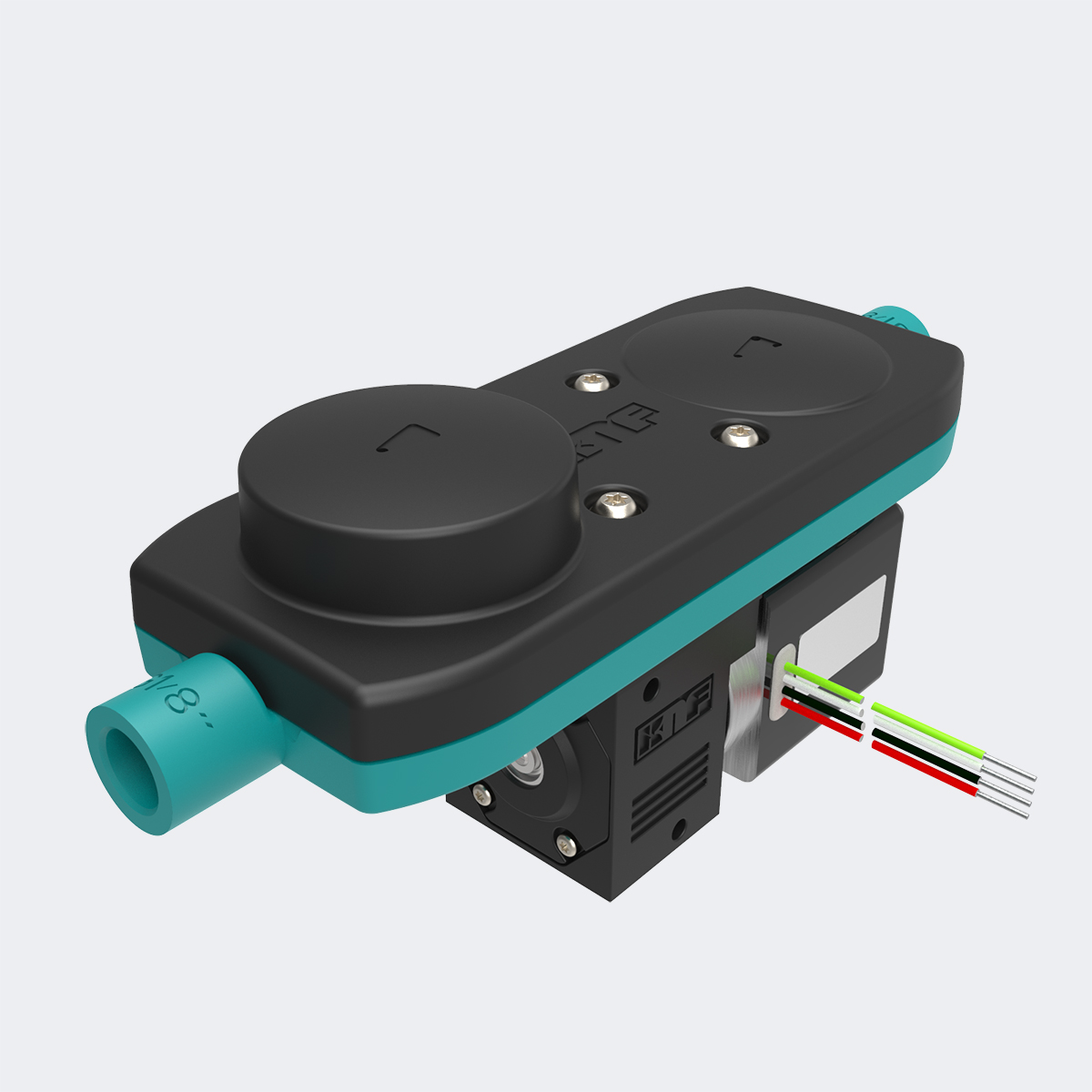

One of the biggest innovations of the new DC-BI motors is their high level of integration. For maximum compactness and robustness, motor, pump housing, ball bearings and eccentric form one single unit. This integration makes the diaphragm pumps lightweight with compact dimensions, resulting in an excellent size-to-performance ratio. The newly developed housing also improves the pump’s heat management, especially under continuous heavy load. By increasing the size of the ball bearings and optimizing their placement, the lifetime of the pump can be increased significantly.

Customizing Option for Many Pumps

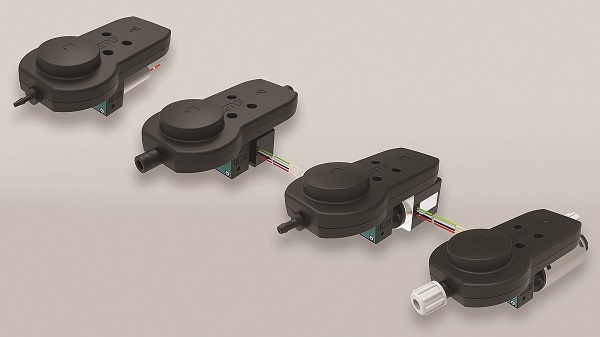

KNF offers DC-BI motors as a customization for several micro gas pumps and liquid pumps. Micro gas pumps that can be fitted with the new motor include NMP 830 and NMP 830 HP as well as NMP 850 and NMP 850 HP. Liquid pumps available with this customization option are NF 30, NF 60 and FP 70. KNF plans to offer multiple standard pump series that rely on the modern DC-BI motor.

View website