Flow sensor solutions for ventilators that include connectors and cable interfaces were launched in February 2019. They enable patient-side measurement of inhalation and exhalation flows. The different stand-ardized variants are available to medical technology OEMs free of development and tooling costs. They are the product of the cooperation between the sensor manufacturer Sensirion AG and medical technology cable and connector specialist Nicolay GmbH.

March 2019, Sensirion AG, 8712 Staefa, Switzerland

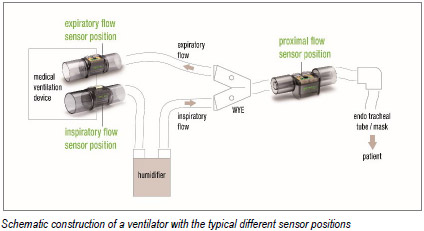

The requirements for patient-oriented ventilation which takes individual pathophysiology of the patient into account represents a challenge to the manufacturers of modern ventilators. It requires highly accurate inspiratory and expiratory gas flow measurements. Classic sensors installed inside a ventilator and distal from the patient make it difficult to achieve the required accuracy. Nicolay and Sensirion took on this challenge and launched a sensor-connector-cable solution that provides accurate, patient-side measurement while delivering a reliable flow signal to the ventilator. The solution includes different options of cables and connectors in order to reliably transport calibrated and temperature-compensated output signals of the sensor back to the ventilator. These options also ensure, among other features, compatibility with a variety of communication protocols. This sensor-connector-cable combination is now also available in Distribution.

The requirements for patient-oriented ventilation which takes individual pathophysiology of the patient into account represents a challenge to the manufacturers of modern ventilators. It requires highly accurate inspiratory and expiratory gas flow measurements. Classic sensors installed inside a ventilator and distal from the patient make it difficult to achieve the required accuracy. Nicolay and Sensirion took on this challenge and launched a sensor-connector-cable solution that provides accurate, patient-side measurement while delivering a reliable flow signal to the ventilator. The solution includes different options of cables and connectors in order to reliably transport calibrated and temperature-compensated output signals of the sensor back to the ventilator. These options also ensure, among other features, compatibility with a variety of communication protocols. This sensor-connector-cable combination is now also available in Distribution.

High-Quality Sensor Technology

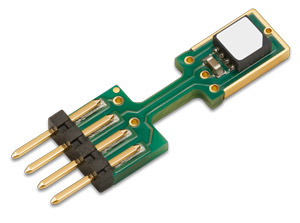

The Sensirion Flow Meter (SFM) is available either in autoclavable and washable (AW) variants or as single-use solutions (D = disposable). The SFM3400 was developed for neonatal applications, that means for measuring very small volumes, while the SFM3300 was developed for adult ventilation. The SFM3200 is intended for expiratory applications. The performance of these gas flow sensors is based on technology developed and patented by Sensirion that combines the sensor element, signal processing and digital calibration on a single microchip. The flow rate of gases is measured using a microthermal sensor element that among other advantages, enables a wider dynamic measurement range and superior long-term stability compared to other measurement principles. All flow meters come factory calibrated which makes them straightforward to use without prior or repeated calibration.

Modern Connector and Cable Variants

All sensor variants can be connected to the ventilator using the Nicolay Flow Meter Connector. This robust mechanical interface is incredibly easy to use; it attaches easily and only in the intended manner to ensure correct use even in fast-paced situations. When connected, the interface is leak-proof to protection rating IP54, and when detached it allows for wipe disinfection. Communication with the sensor I²C bus using short cable lengths requires nothing more than a connection with simple spring contacts. A secure signal transfer over longer cables utilizes electronics integrated into the connector to convert the signals. When equipped with an RS485 or RS232 interface, the device translates the signals ready for the ventilator's common communication protocols. There is also a range of connector options available, for example the Nicolay mini7 or mini12 interfaces. In addition to the standardized product variants, customer-specific PCB layouts can also be realized and integrated into the connector.

Buy Ready-Made – or Outsource

This readily available high-quality solution by Nicolay and Sensirion offers ventilator manufacturers an alternative to individually produced sensor connector and cable configurations. They are attractive for evaluation purposes, early stages of development or in smaller quantities, for instance when investment in in-house development and tools is time-sensitive or financially not justifiable. The range of different cabling options makes these standardized variants an attractive alternative to in-house development be-cause sensors and cables used for patient monitoring require specialist expertise. These medical device components are often out-sourced by OEMs – which leads us back to the reason why Nicolay and Sensirion partnered for this solution.

This readily available high-quality solution by Nicolay and Sensirion offers ventilator manufacturers an alternative to individually produced sensor connector and cable configurations. They are attractive for evaluation purposes, early stages of development or in smaller quantities, for instance when investment in in-house development and tools is time-sensitive or financially not justifiable. The range of different cabling options makes these standardized variants an attractive alternative to in-house development be-cause sensors and cables used for patient monitoring require specialist expertise. These medical device components are often out-sourced by OEMs – which leads us back to the reason why Nicolay and Sensirion partnered for this solution.

About Sensirion – Experts for Environmental and Flow Sensor Solutions

Sensirion AG, headquartered in Staefa, Switzerland, is a leading manufacturer of digital microsensors and systems. The product range includes gas and liquid flow sensors, differential pressure sensors and environmental sensors for the measurement of humidity and temperature, volatile organic compounds (VOC), carbon dioxide (CO2) and particulate matter (PM2.5). An international network with sales offices in the US, Europe, China, Taiwan, Japan and Korea supplies international customers with standard and custom sensor system solutions for a vast range of applications. Sensirion sensors can commonly be found in the medical, industrial and automotive sectors, analytical instruments, consumer goods and HVAC products.

One of the hallmark features of Sensirion products is the use of its patented CMOSens® Technology, which permits intelligent system integration of the sensor element, logic, calibration data and a digital interface on a single chip. Sensirion's credentials as a reliable supplier are underscored by its loyal customers, quality reputation (ISO/TS 16949) and top customer pedigree.

Contact: www.sensirion.com, [email protected], Tel. +41 44 306 40 00, Fax +41 44 306 40 30

About Nicolay GmbH

Nicolay GmbH is based in Nagold and develops and manufactures cable systems, connector systems and sensors that are used around the world in non-invasive patient monitoring and diagnostics. Founded in 1964 as a plastic injection molding plant, the company is now known for the high quality of its customer-specific medical technology solutions that frequently form the link between monitor and patient. With its extensive expertise, the company is not only a reliable supplier, but also an application consultant and problem solver. For complex products in particular, Nicolay’s experts often take on the entire development process for its customers.

Together with its manufacturing plant in Tirgu Mures, Romania, the company currently employs around 320 members of staff and generates an annual revenue of around EUR 32 million.

Nicolay is certified to DIN EN ISO 13485 (quality management) and DIN EN ISO 14001 (environmental manage-ment) standards.

You can find more information at www.nicolay.de.