Vermont-based advanced manufacturing company grows local high school training program

BETHEL, VT (January 19, 2016) – In response to a growing regional and national skilled labor shortage, GW Plastics is leading the way in workforce training, career development, and community educational outreach through their innovative high school program. Last week, GW Plastics celebrated the graduation of their second "School of Tech" class and is proud to announce the steady growth of the program.

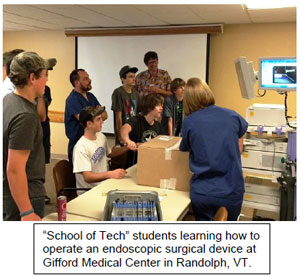

GW Plastics began their “School of Tech” in 2015 after two years of planning with local state and school officials. The semester-long program focuses on raising awareness among local youths about careers in advanced manufacturing. “It is very difficult to find a high school shop class that provides relevant training in our industry,” says Cathy Tempesta, GW Plastics Director of Human Resources. “There are limited ways for students to become exposed to the world of manufacturing, so we launched our own „school‟ in order to make manufacturing attractive again.” GW Plastics recruits their own employees in collaboration with high school teachers to instruct the students on all things manufacturing, including polymer science, product design, mold building, injection molding, automation, quality assurance, and general business skills. Each semester includes a visit to Gifford Medical Center in Randolph where the students can see GW Plastics‟ healthcare products used in real life and learn about the ramifications if a device is not manufactured to the highest level of quality possible.

In just two semesters, the program has grown in popularity and includes actual interaction with advanced machine tools, molding machines, and other technologies instead of just classroom instruction. This semester's students took it a step further, and by the end of the semester they had not only studied manufacturing techniques, but they also designed and manufactured their own product - cell phone holders that are now being sold at their school. This real-life process helps the students understand everything from concept through production including the satisfaction of bringing a product to market.

GW Plastics‟ innovative and holistic “School of Tech” program makes students think in a more sustainable and global way, ultimately creating experienced and knowledgeable young professionals. "We could not be more thrilled that these students are as engaged as they are in this program," said Tempesta. "Most of these students have never been in a manufacturing environment before, and now they have successfully designed and manufactured their own product. These experiences that the students are now able to list on a future college or job application are unparalleled."

GW Plastics already has plans to expand the “School of Tech” program, with the next semester of students starting at the end of January. They have also broken ground on their Royalton, VT site expansion, which will allow for extra classrooms and enhanced training facilities for the students to use. "We are delighted to be able to give back to our community and our local students to help them prepare for wherever their career interests take them," said Brenan Riehl, GW Plastics President and CEO. "Our investment in these students and commitment to this program runs deep, and we are thrilled to have both the facilities and the volunteer staff to help expand our program and restore excitement to a career in manufacturing.”

Please join GW Plastics in congratulating the following students on a successful semester: Nathan Gray, Ethan French, Zavier Henderson, Cameron Jarvis, Gurion Lake, Alexander Russell, and Connor Wheatley. In addition, GW Plastics would like to extend sincere gratitude to Randolph Union High School teacher Ken Cadow for his dedication to this program and the staff of RUHS for their ongoing support.

To learn more about the “School of Tech” program and GW Plastics‟ workforce training initiatives, please contact Cathy Tempesta at [email protected] or visit their website at www.GWPlastics.com.

About GW Plastics:

Since its foundation in 1955, GW Plastics has earned a reputation as a leader in precision injection molding and contract manufacturing serving the world‟s most successful companies in the healthcare, automotive safety, and consumer/industrial markets. Specializing in complex injection molded thermoplastic and silicone solutions, GW Plastics excels at close tolerance mold building, precision injection molding, and contract assembly. Core competencies include product development, in-house precision tooling, scientific molding, and automated assembly. With leading-edge technologies, a Six Sigma quality commitment, and a relentless pursuit of innovation, GW Plastics continues to attract and delight industry-leading market leaders who seek consistency of ownership, financial stability, a professional leadership team, and a workforce with the experience to deliver ontime and within budget. Headquartered in Bethel, Vermont, the company‟s standardized ISO 9001, ISO 13485, ISO/TS 16949 and FDA-registered manufacturing facilities are located in Bethel and Royalton, Vermont; San Antonio, Texas; Tucson, Arizona; Querétaro, Mexico; and Dongguan, China.

For more information, contact:

Rebecca Murphy

Inside Sales and Marketing Coordinator

GW Plastics, Inc.

239 Pleasant Street

Bethel, VT 05032

(802) 234-9941

[email protected]