Enercon to demonstrate its newest blown ion plasma surface treater

Menomonee Falls, Wisconsin, USA - Professionals in the plastics industry looking to improve the performance of plastics through in-line surface treating will be spending time with the experts from Enercon Industries Corporation in Hall 11 Stand A68. Corona, Atmospheric Plasma and Flame Surface Treating Technologies will be on display at the Enercon booth for both films and objects.

Technologies for treating objects

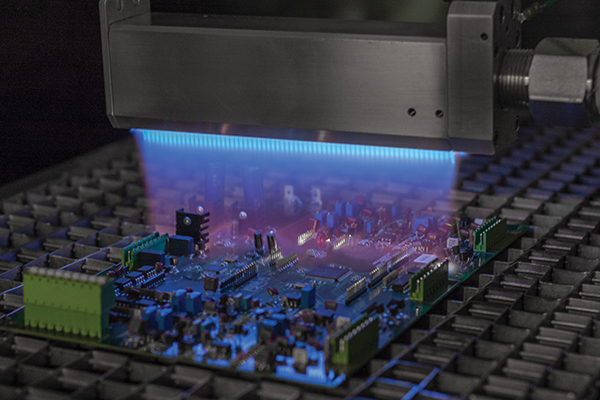

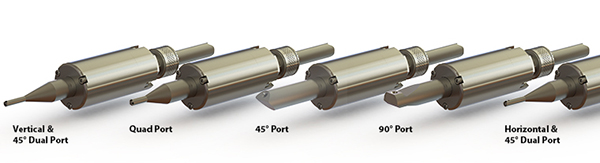

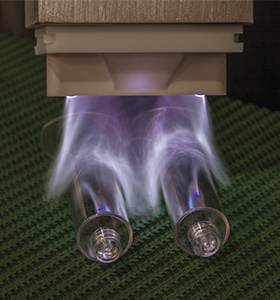

Enercon will demonstrate its newest blown ion plasma surface treater with robot integration. These systems are designed to clean, etch and functionalize surfaces to improve the adhesion of inks, adhesives and coatings. Visitors to the booth will be able to test the powerful touch screen operator interface on the new blown arc plasma that unlocks a host of powerful features. Also on display will be Enercon’s flame surface treating systems featuring advanced combustion control and high velocity burner designs.

Additional Technologies on Display

Film extruders will get a firsthand look at corona treaters specifically designed for blown film lines with capabilities for fixed width, lane and pattern treatment. Printing, coating, and laminating converters of film will see the latest electrode, ground roll and power supply designs for improving film and label stock surface adhesion.

Enercon’s Super Seal™ Touch Cap Sealer will be in operation showcasing its powerful touch screen interface and reliable induction sealing capabilities. Induction sealing creates a hermetic seal that prevents leaks, preserves freshness and provides tamper evidence.

Enercon Industries Corporation, headquartered in Menomonee Falls, WI, USA is a major international manufacturer of equipment for the plastics, converting and packaging industries. The company supplies custom built corona and atmospheric plasma treating systems, as well as induction cap sealing systems.

###

View website