CATHTIP and sister companies, Cath-Punch and Production Medical, unite to offer customers more robust, streamlined solutions for all their catheter product needs.

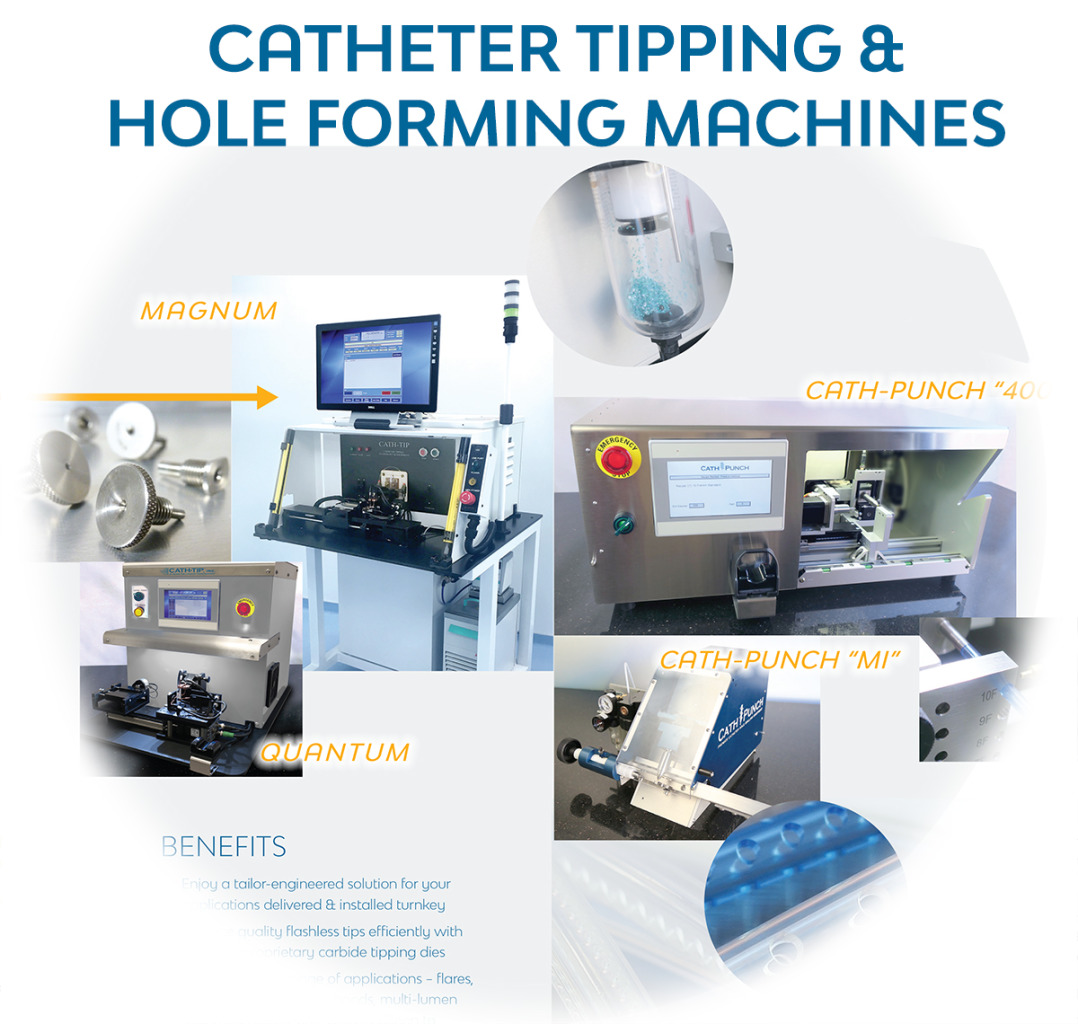

CATHTIP provides proof-of-concept, rapid prototyping, process development, catheter tipping machines, hole forming equipment and clean room manufacturing.

CATHTIP’s Proven Process moves your new development project quickly from the concept stage to production.

You receive proof-of-concept samples speedily because we maintain over 400 dies and drills in our library. During this initial step we can provide suggestions on geometry and material selection to optimize device performance and manufacturability. Custom tooling is then designed and built in our in-house tooling shop to meet your final specifications. After the tooling is complete prototype samples are produced.

Once the design of the prototypes is verified and approved, we develop a robust, semi-automated process. Then, it’s your choice whether to have CATHTIP run production or to purchase equipment for your own facility. If you choose to run production at your site, we can assist you with machine/process training and IQ/OQ. Equipment customers find value in keeping 10-20% of production with us to ensure their supply chain with the same machines, tooling and processes.

Either way, you can be sure the end result will be high quality parts using our flashless tipping technology and burr-free hole forming equipment.

ISO 13485:2016 Certified Quality Management System