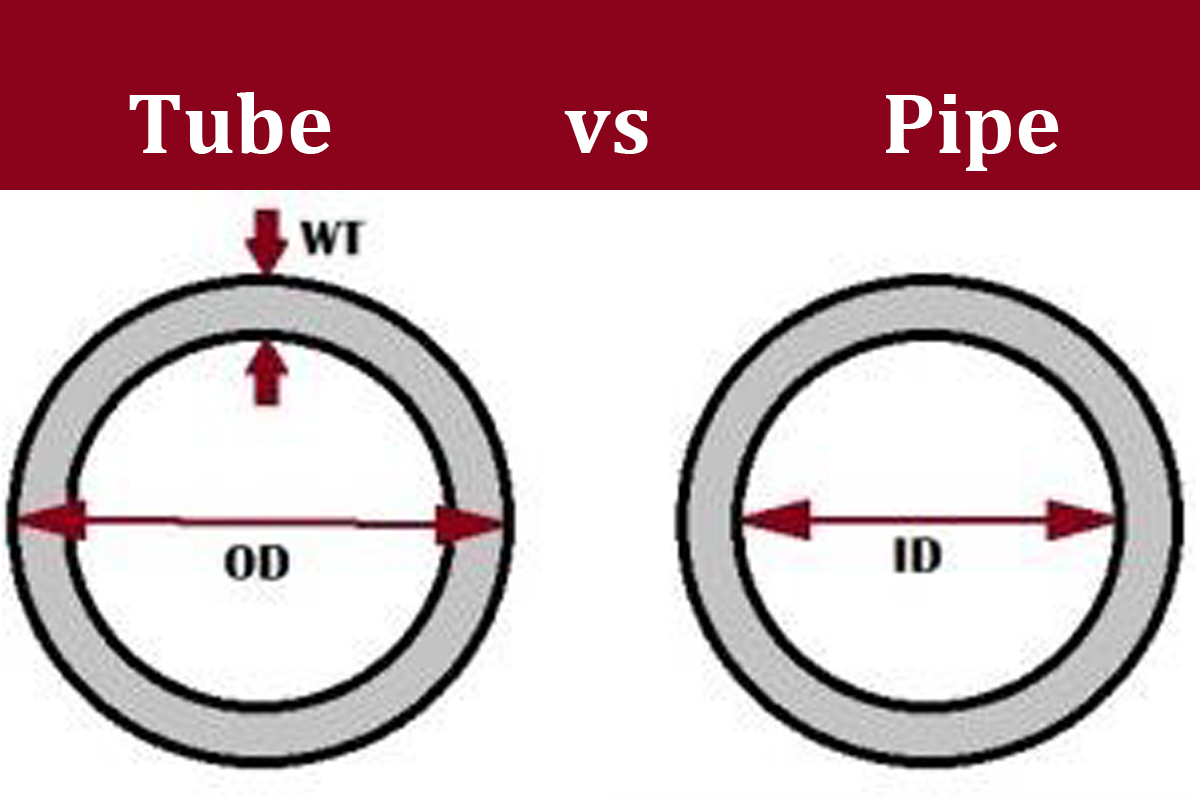

In some instances the terms may be used interchangeably, however there is one key difference between tube and pipe, particularly in how the material is ordered and toleranced.

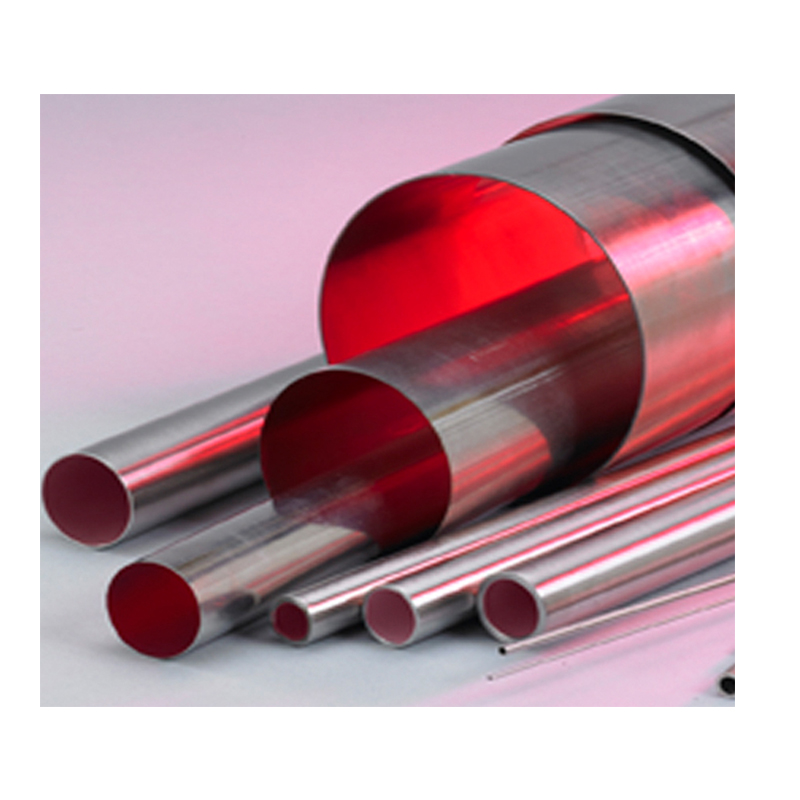

Tubing is used in structural applications so the outside diameter becomes the important dimension. Tubes are often put into applications such as medical devices that require precise outside diameters. The outside diameter is important since it will indicate how much it can hold as a stability factor. Where as pipes are normally used to transport gasses or liquids making it important to know the capacity. Knowing how much can flow through the pipe is key. The circular shape of the pipe make it efficient when handling pressure from the liquid flowing through.

Classification

Tubes are typically ordered to outside diameter and wall thickness; however, it may also be ordered as OD & ID or ID and Wall Thickness. The strength of a tube depends on the wall thickness. The thickness of a tube is defined by a gauge number. Smaller gauge numbers indicate larger outside diameters. The inside diameter (ID) is theoretical. Tubes can come in different shapes such as square, rectangular and cylindrical, whereas Pipe is always round. The circular shape of the pipe make the pressure force evenly distributed. Pipes accommodate larger applications with sizes that range from a ½ inch to several feet. Tubing is generally used in applications where smaller diameters are required.

Ordering Your Tubing or Pipe