Coordinated process of marking and passivation guarantees long time legibility, according to UDI regulations for traceability

August 9, 2017

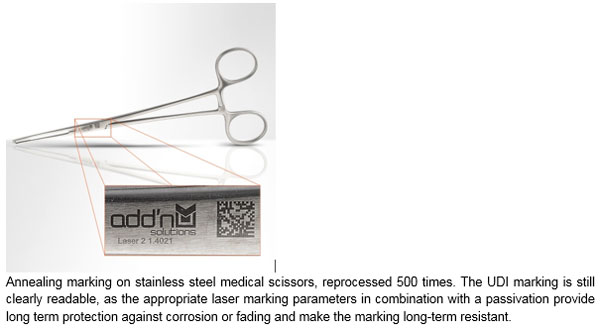

In close cooperation with FOBA Laser Marking + Engraving, “add’n solutions GmbH & Co. KG” of Tuttlingen/Germany, a service provider for UDI laser marking on medical devices, conducted a long term study on reusable surgical instruments. The aim was to prove that laser marks remain clearly readable in spite of multiple reprocessing procedures. The UDI must resist increased wear throughout the whole product life cycle to ensure safe traceability, which is also officially required.

The study is comprehensively documented and has for the first time demonstrated that laser marked high contrast codes are able to resist at least 500 sterilization and cleaning cycles. FOBA’s short pulse fiber marking lasers have been optimally adapted to the surface characteristics of different types of stainless steel. The appropriate laser parameters prevent the inscription from fading out or corroding. An additional passivation ensures that the complete device, including marked areas, is protected against corrosion. The American standard for the passivation of stainless steel, ASTM 967, was used for the passivation of the instruments.

“add’n solutions” utilized a precisely matched laser marking process, followed by a cleaning and passivation cycle. The surgical instruments were finally sterilized and cleaned 500 times, simulating actual wear conditions in a hospital. The steam sterilization was accompanied by an instrument cleaning with high alkaline cleaners (pH value 14), which is also equivalent to clinical cleaning procedures.

A direct mark on a medical product must not only be of high contrast and resistance, it also cannot have a negative impact on the surface quality. Until recently, it was unknown how often laser marked surgical instruments can be reprocessed without negatively impacting the quality of the mark.

Notwithstanding the type of laser used – short or ultra-short pulse laser – the recent study provided evidence that only an additional passivation, developed to exactly match the marking process, creates appropriate long term protection against corrosion and thus ensures the readability of the marks.

Data regarding the sustainability of ultra short pulse laser marks, created for example with pico or femto second lasers, is apparently still not available. The present study suggests that the assumption, that marking with ultra-short pulse laser does not require passivation, is incorrect. Only accompanied by a passivation process can the complete product be reliably protected.

The latest legal regulations of the American FDA (Federal Drug Association) and the European Medical Device Regulation require that all medical products have to bear marks, with implementation deadlines that vary according to the risk class of the device. FOBA’s fiber laser markers enable a reliable, efficient, fast and, due to the prevention of scrap, cost effective implementation of the valid marking standards.

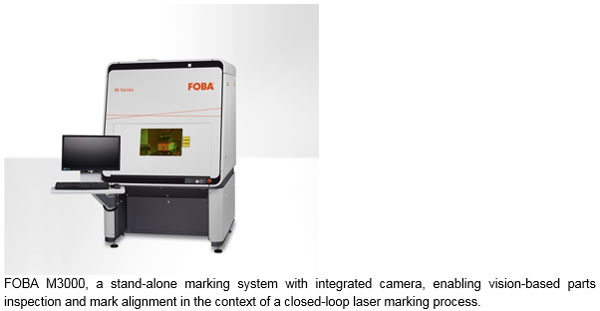

“add’n solutions”’ durability test confirms the company’s expertise as a specialized service provider for medical device manufacturers in UDI marking. The management states to provide the best possible marking results for their customers, using FOBA’s vision based marking technology. The parts marking process therefore includes an automatic optical verification of the marking results within a validated procedure.

An application case study with a detailed description of the durability test on reusable surgical instruments is available for free download on the FOBA website www.fobalaser.com

Alltec GmbH | FOBA Laser Marking + Engraving

www.fobalaser.com

For additional information please contact:

Susanne Glinz | Campaign Manager

ALLTEC GmbH | FOBA Laser Marking + Engraving

An der Trave 27 – 31 | 23923 Selmsdorf/ Germany

Tel.: +49 (0)38823 55-547 | Fax: +49 (0)38823 55-222

[email protected] | www.fobalaser.com

About FOBA www.fobalaser.com

FOBA Laser Marking + Engraving is among the leaders in manu¬factur¬ing and supplying precision laser systems for marking and engraving. FOBA marking lasers mark a variety of materials and parts not least in the key markets of Automotive and Medical but also in Electronics, Plastics, Safety and ID. FOBA laser workstations for marking and engraving are especially applied in the fields of Automotive part production and Medical device marking as well as in Tool, Metal and Mold Making, Plastics processing and Jewelry. Worldwide sales and service branches service the most important markets.

In September 2009, FOBA has become part of ALLTEC GmbH. Since then, FOBA is part of ALLTEC as a sales channel for laser part marking and engraving.